Solar wafers are the fundamental building blocks of solar cells, which are the key components in solar panels used to generate electricity from sunlight. These wafers are typically made from crystalline silicon, though they can also be produced using other materials like thin-film technologies (such as cadmium telluride or copper indium gallium selenide).

The process of manufacturing solar wafers involves slicing a high-purity silicon ingot into ultra-thin, circular discs. These discs, known as wafers, undergo surface texturing and doping (adding specific impurities to alter electrical properties) to form the basis of solar cells.

The primary type of solar wafer is the crystalline silicon wafer. There are two main types:

Monocrystalline Silicon Wafers: These are cut from single-crystal ingots and offer higher efficiency due to the uniform crystal structure, resulting in better electron flow.

Polycrystalline Silicon Wafers: These wafers are made from multiple silicon crystals, providing a less expensive alternative to monocrystalline wafers but with slightly lower efficiency.

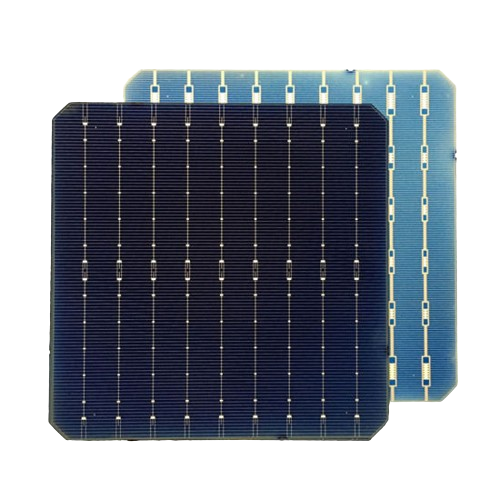

Solar Wafer

Swift Delivery

Small Quantities Welcome

High Quality

SOLAR WAFER

Solar wafers are the fundamental building blocks of solar cells, which are the key components in solar panels used to generate electricity from sunlight. These wafers are typically made from crystalline silicon, though they can also be produced using other materials like thin-film technologies (such as cadmium telluride or copper indium gallium selenide).

The process of manufacturing solar wafers involves slicing a high-purity silicon ingot into ultra-thin, circular discs. These discs, known as wafers, undergo surface texturing and doping (adding specific impurities to alter electrical properties) to form the basis of solar cells.

The primary type of solar wafer is the crystalline silicon wafer. There are two main types:

Monocrystalline Silicon Wafers: These are cut from single-crystal ingots and offer higher efficiency due to the uniform crystal structure, resulting in better electron flow.

Polycrystalline Silicon Wafers: These wafers are made from multiple silicon crystals, providing a less expensive alternative to monocrystalline wafers but with slightly lower efficiency.

The process of manufacturing solar wafers involves slicing a high-purity silicon ingot into ultra-thin, circular discs. These discs, known as wafers, undergo surface texturing and doping (adding specific impurities to alter electrical properties) to form the basis of solar cells.

The primary type of solar wafer is the crystalline silicon wafer. There are two main types:

Monocrystalline Silicon Wafers: These are cut from single-crystal ingots and offer higher efficiency due to the uniform crystal structure, resulting in better electron flow.

Polycrystalline Silicon Wafers: These wafers are made from multiple silicon crystals, providing a less expensive alternative to monocrystalline wafers but with slightly lower efficiency.

P-Type Solar Wafer Specifications

| Size | M4 | M6 | M10 | M12 |

| Geometry | Quasi Square | |||

| Wafer Side length | 161.7±0.25 mm | 166±0.25 mm | 182±0.25 mm | 210±0.25 mm |

| Wafer Diameter | φ221±0.25 mm | φ223±0.25 mm | φ247±0.25 mm | φ295±0.25 mm |

| Resistivity | 0.5-1.5 Ωcm | |||

| Lifetime | ≧50 μs | |||

| Oxygen concentration | ≦8E+17 at/cm3 | |||

| Carbon concentration | ≦5E+16 at/cm3 | |||

N-Type Solar Wafer

| Size | G1 High Resistivity | G1 Low Resistivity | M0 | M1 | M2 |

| Geometry | Full square | Full square | Pseudo square | Pseudo square | Pseudo square |

| Wafer Side length | 158.75±0.25 mm | 158.75±0.25 mm | 156.0±0.25 mm | 156.0±0.25 mm | 156.0±0.25 mm |

| Wafer Diameter | φ223±0.25 mm | φ223±0.25 mm | φ210±0.25 mm | φ205±0.25 mm | φ210±0.25 mm |

| Resistivity | 1.0-7.0 Ω.cm | 0.3-2.1 Ω.cm | ≧1Ω.cm | ≧1Ω.cm | ≧1Ω.cm |

| Lifetime | ≧500 μs | ≧1000 μs | ≧1000 μs | ≧1000 μs | ≧1000 μs |

| Oxygen concentration | ≦8E+17 at/cm3 | ≦8E+17 at/cm3 | ≦8E+17 at/cm3 | ≦8E+17 at/cm3 | ≦8E+17 at/cm3 |

| Carbon concentration | ≦5E+16 at/cm3 | ≦5E+16 at/cm3 | ≦5E+16 at/cm3 | ≦5E+16 at/cm3 | ≦5E+16 at/cm3 |

EN

EN JA

JA